ORYZITE, THE

SUSTAINABLE

ALTERNATIVE TO

PLASTIC

ORYZITE, THE SUSTAINABLE

ALTERNATIVE TO PLASTIC

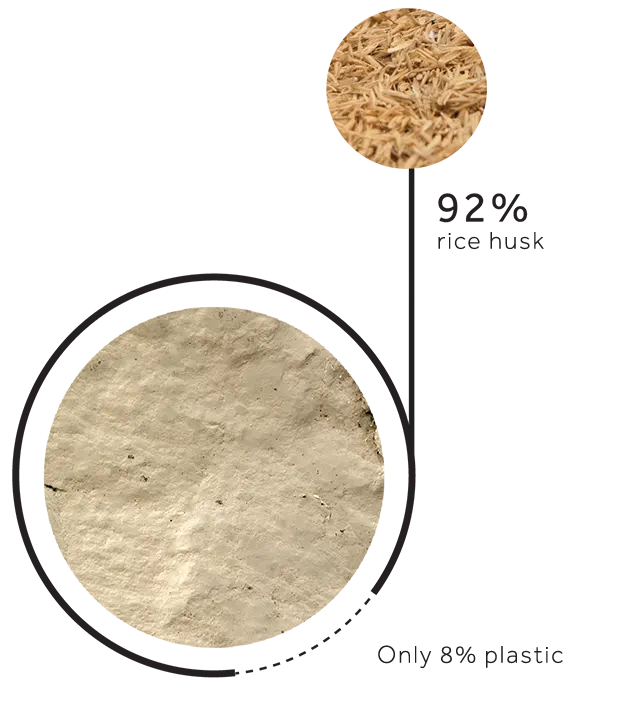

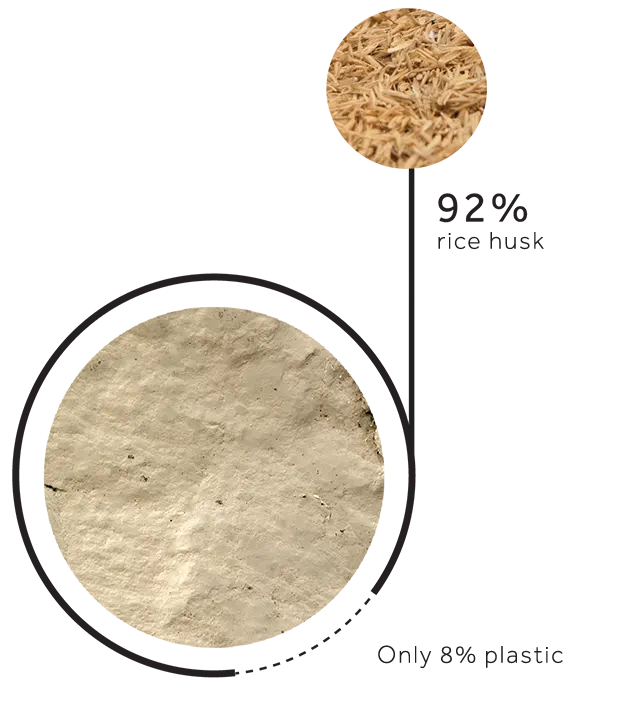

Rice husk instead of plastic

Oryzite is a globally patented method for incorporating rice husk into all types of thermoplastic compounds. It is the result of an R&D project initiated 15 years ago by Iban Ganduxé (Oryzite CEO) and the Montsià Chamber of Rice. The initiative began as a way to make use of the excess rice husk from the millions of tonnes of rice that are produced each year. This is one of the largest agro-industrial by-products in the world, and it cannot be digested by humans or animals.

Thanks to Oryzite’s technology, it is now possible to offer a sustainable alternative to plastic. Rice husks are transformed into a raw material that can replace plastic, thereby reducing its use and waste, as well as the environmental impact of its production.

Every year, approximately 750 million tonnes of rice are produced worldwide.

20% of that is husk.

Oryzite production is carried out at the same Montsià Chamber of Rice plant that processes rice. It has processing facilities of some 34,000 m2, and the rice is cultivated over an area of 8,400 hectares. The Chamber produces around 60,000 tonnes of rice each year with the capacity to produce 14,000 tonnes of Oryzite annually. What’s more, this model is replicable worldwide, wherever rice is grown.

That’s why at Novsus we have chosen Oryzite as the basis for all of our eco-friendly cosmetic packaging.

Benefits

for the environment

SECOND LIFE FOR A WASTE PRODUCT

The rice grain has to be separated from its husk for human consumption. Oryzite reuses this agricultural waste, thus saving the emissions resulting from its destruction.

MINIMAL NATURAL RESOURCES

The conversion process from husk to Oryzite does not require water and uses only minimal energy. A single kWh is enough to produce 16 kg of Oryzite.

LOCAL PRODUCTION

This is a locally-produced product, as Oryzite production plants are located in the same area the rice is grown.

CARBON CAPTURE

The molecular structure of the rice husk captures and fixes carbon.

SECOND LIFE FOR A WASTE PRODUCT

The rice grain has to be separated from its husk for human consumption. Oryzite reuses this agricultural waste, thus saving the emissions resulting from its destruction.

MINIMAL NATURAL RESOURCES

The conversion process from husk to Oryzite does not require water and uses only minimal energy. A single kWh is enough to produce 16 kg of Oryzite.

LOCAL PRODUCTION

This is a locally-produced product, as Oryzite production plants are located in the same area the rice is grown.

CARBON CAPTURE

The molecular structure of the rice husk captures and fixes carbon.

A truly sustainable process from beginning to end

In recent years, there has been an increase in the use of raw materials in cosmetic packaging that claim to be and are perceived as 100% eco-friendly. But, to what extent are they? Is the real impact of how they are procured being taken into account?

To obtain wood, there are many steps involved that require high consumption of different types of energy: from tree planting, transport, and handling of the logs, to drying, sorting, grading and planing the wood.

Obtaining rice husks only requires three steps, which are already in place to procure the grain for human consumption anyway: cultivation, harvest and separation of the husks. What’s more, transportation is not necessary because Oryzite production is carried out in facilities located in the same cultivation area, so the total emissions generated are therefore minimal. Thanks to this sustainable process, we minimise the consumption of natural resources and have a positive impact on the planet.

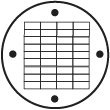

Comparison of processes for obtaining raw materials

Rice husk

VS.

Wood

1

Rice cultivation

2

Harvest

3

Cleaning and

husking

Total impact

Only 3 steps and

1

Tree planting

2

Felling trees

3

Log transportation

4

Handling and stripping of bark

5

Log sawing

6

Drying

7

Grading and planing

8

Transportation to final product manufacturer

Total impact

8 steps and

Consumption of natural and/or energy resources

Related

technical benefits

Reduces the production cycle of the final product.

Provides strength and dimensional stability.

Lower moisture absorption.

Flame retardant properties.

Efficiently reduces raw material costs.

Reduces the production cycle of the final product.

Provides strength and dimensional stability.

Lower moisture absorption.

Flame retardant properties.

Efficiently reduces raw material costs.

Provides strength and dimensional stability.

Lower moisture absorption.

Flame retardant properties.

Efficiently reduces raw material costs.

Reduces the production cycle of the final product.

How do we develop specific eco-friendly materials for cosmetic packaging from Oryzite?